2/3/2023

How to achieve the corrosion resistance of epoxies and weather resistance of polyurethane coatings in a single coat system, where the use of isocyanates is not desired? By choosing Norecryl 50, an isocyanate-free acrylic coating.

The corrosion resistance of epoxies is excellent. In paint systems, they are often used as a primer in order to achieve the desired corrosion class. As a topcoat, epoxies can only be used indoors, as they cannot withstand sunlight. Outdoors, epoxies chalk and fade quickly.

Polyurethane coatings, on the other hand, have been widely used as topcoats due to their excellent weatherability. They can withstand UV radiation for years. In addition, they help with corrosion resistance. However, polyurethane coatings contain isocyanates, which some customers do not want to use in their processes.

Epoxy and polyurethane coatings can be combined into excellent paint systems, but then several layers are required and the systems contain isocyanate.

Veisto Oy

Norecryl 50 combines the best properties of epoxies and polyurethanes: corrosion and mechanical resistance as well as weather resistance and smooth finish.

Norecryl 50 differs from many other coatings specifically with its excellent anti-corrosion properties. The product is used as a direct-to-metal coating in corrosion class C4 medium with a 120 µm DFT. In ISO 12944-5 protective paint systems, C4 medium corrosivity category paint systems have a total dry film thickness of 180 µm. In addition, the systems usually consist of two layers of paint. Norecryl 50 can be sprayed as a single-coat system, which, in addition to the film thickness advantage, also saves time, because the finished surface is obtained with one coat of paint.

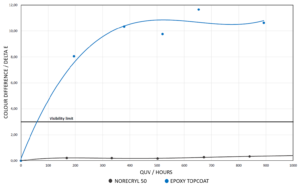

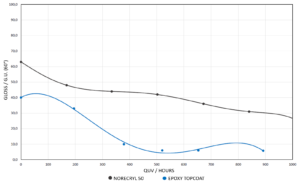

Norecryl 50 is comparable to epoxies in terms of its corrosion resistance, but differs from them due to its weather resistance. While epoxy chalks and fades in sunlight, Norecryl 50 retains its colour and gloss. The following graphs show the colour and gloss retention of Norecryl 50 in an accelerated weathering test (ISO 16474-3). A two-component polyamide cured epoxy topcoat was chosen as a reference product for the test.

In terms of colour retention, the difference between Norecryl 50 and epoxy coating is significant. With Norecryl 50, the colour difference is not visible even over a long period of time, while with epoxy topcoat, the colour changes and fades in short UV exposure. The colour retention of Norecryl 50 is comparable to the colour retention of polyurethane coatings.

The gloss retention with Norecryl 50 is much better than with epoxy coating. With epoxy topcoat, the gloss decreases quite sharply and disappears completely, while with Norecryl 50 the gloss decreases gradually. The product does not become dull like epoxy coating. The gloss retention of Norecryl 50 could be compared to alkyd or moderate polyurethane coating.

Isocyanate-free Norecryl 50 offers a cost-effective alternative for corrosion protection and weather resistance. The product has pot-life of 3.5 hours, which is long compared to many two-component polyurethane coatings. Paint loss is minimized and objects to be painted can be completed by single spraying. Throughput time is faster than with two-layer systems. Norecryl 50 is suitable for machinery and equipment and general steel structure projects.

Contact our sales for more info.

Veisto Oy

Veisto Oy. Norecryl 50 is a weather-resistant alternative to epoxy coating.