14/4/2021

When painting with Nor-Maali´s water-borne coatings, for example Normadur Aqua DTM, stable conditions ensure a robust and a premium film. Besides the environment conditions, such as humidity and temperature, there are several practical tips to be kept in mind, says Miika Bergdahl, Nor-Maali’s test painter. Read here below more of Miika and his tips for applying Normadur Aqua DTM.

Miika has worked in spray painting for 25 years, and he has comprehensive experience in industrial paints and coatings as a painter at ACE/OEM company. Miika joined Nor-Maali in the fall 2018.

Miika Bergdahl

After starting to work in Nor-Maali, Miika’s view of industrial coatings and the factors influencing the “fit and use” have broadened considerably. In order for a customer to have a functioning product, considerable amount of R&D and testing shall be done – one crucial part is test painting. In Nor-Maali’s R&D work, cooperation between the chemist and the test painter, plays an important role. The best result is thought and tested together.

In addition to the R&D work Miika’s other tasks include e.g. painting of test plates for various needs (e.g. for Silko and SSG standard test), daily quality control paintings, spraying of sample plates.

Test painting at customer´s is the best way to learn and understand what are the specific needs. Part of Nor-Maali’s technical service concept is test painting at customer´s premises, in which Miika also sometimes participates.

Most of the painting is done with an airless spray, sometimes the work also includes air-assisted gravity feed spraying, and brushing as well as rolling. Usually the surface to be painted is sandblasted steel, but sometimes paintings are made e.g. for smooth steel and galvanized and aluminum surfaces.

Miika says that his current job differs significantly from his previous job in the industry. In the work of a test painter, spraying must be done really accurately. There cannot be any variation in film thickness, as usually the painted plate goes to some test. In Nor-Maali, Miika mainly paints small test plates, while in the previous job he painted large machinery components.

Miika likes his work as test painter, because here he gets to try a lot of different coatings and the effect of different painting methods on the end result. When spraying, different coatings and their painting properties must be taken into account. For example, the spraying properties of epoxy are different from those of polyurethane coating, and a high solid coating requires a calmer hand movement than a product with a lower solid content.

In his free time, Miika builds scale models. He also needs painting skills in his hobby, as an important part of making scale models is painting them with a pencil spray gun and brush.

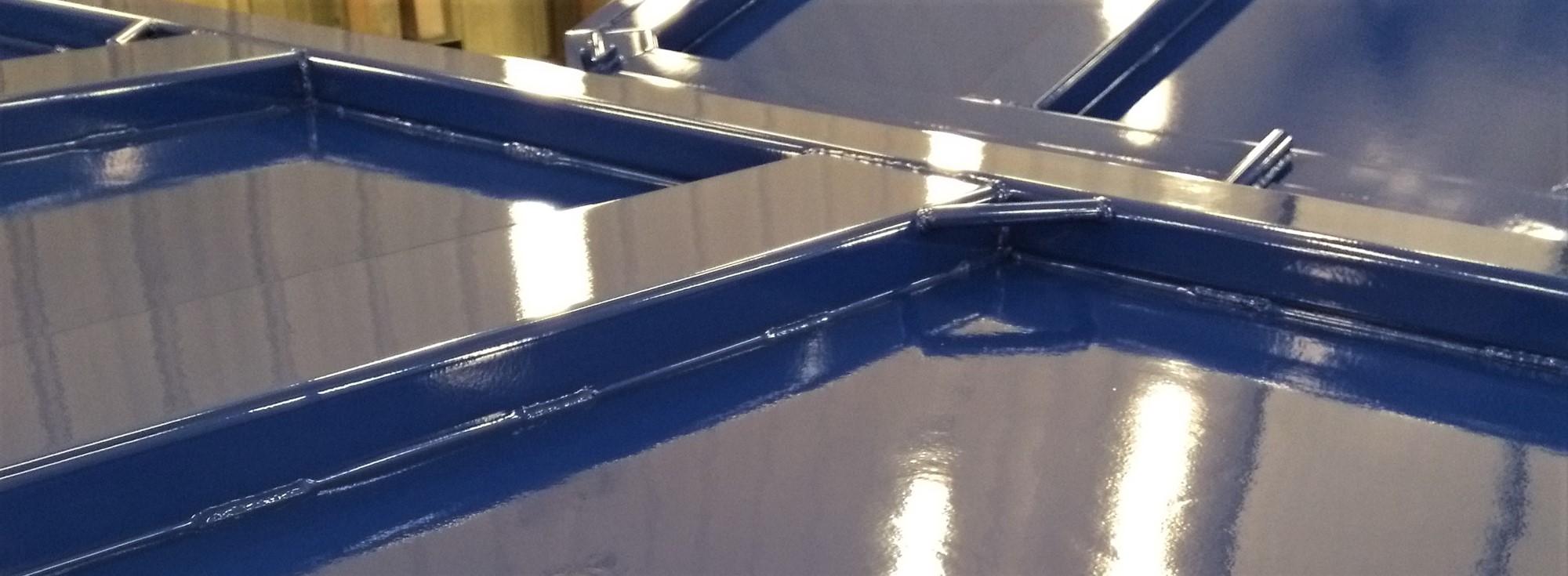

With Nor-Maali´s Normadur Aqua DTM stable conditions ensure a robust film. Miika is painting Normadur Aqua DTM at customer´s premises.

Spraying water-borne polyurethane coating differs from painting many other coatings. This must be done more accurately than spraying solvent-based polyurethane coating. Environmental conditions also need to be further optimized.

Miika’s tips for painting Normadur Aqua DTM:

“When you remember these tips, Normadur Aqua DTM can be used to spray great looking, glossy surfaces. Normadur Aqua DTM is worth a try!” Miika says.