9/2/2021

Nor-Maali offers its customers a comprehensive range of aesthetically pleasing anti-corrosion coatings for steel surfaces. In addition to technical reliability, our products are also spectacular looking. Tinting is an important part of this. Our topcoats are available e.g. in RAL, NCS S, SSG and RR colours. Tinted colours are available also for some primers e.g. Epocoat 21 HB. Tinting has an essential function at our customer service.

Colours hold power: They provoke reactions and influence on behaviour. Colours can be used to inform or draw attention to desired details. Some colours are soothing or they can fade imperfections. The amount and quality of light affects how we see shades.

Colours also play an important role in industrial painting. Colours create images and recognizability for machinery and equipment e.g. in ACE & OEM. Many ACE & OEM-manufacturers have their own brand colour. The colour appearance of a product is important in a sales situation, but colours can also be a safety factor in many industrial applications.

Tinting enables customers to have thousands of shades for the objects they paint. In order to tint a shade, it requires characterized base coating , tinting pastes, a tinting formula created for the product and tinting machine with updated tinting software. Nor-Maali has own tinting systems for solvent-based and water-borne products as well as for Jotun coatings. All dealers in Finland and abroad has the tinting system for Nor-Maali´s solvent-based coatings.

Nor-Maali products are available in RAL, NCS S, SSG, and RR colours. Selection of TM and Munsell colours are also available. In addition to the standard colours, Nor-Maali’s tinting department creates a lot of customer-specific colours. Kristiina Parkkila and Jere Juntunen are responsible for tinting in Nor-Maali.

Tinting reduces companies’ carbon footprint. Instead of producing all the different shades, Nor-Maali produces a few base colours that can be used to tint all the desired colours. Most of Nor-Maali´s topcoats have three different base colours with varying degrees of whiteness. In addition, some of our topcoats are also available in yellow, orange and red base colours. This improves the opacity of the shades. Our dealers carry in their assortment bases and tint locally. Thanks to this, both Nor-Maali and the dealers can service you quickly.

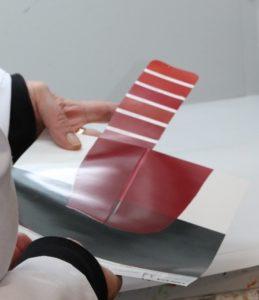

Colour sample from a customer.

The shade can usually be accepted when the colour difference compared to the standard is ΔE < 1. However, the colour is usually accepted visually, the colour difference information provided by the spectrophotometer only acts as a tool in the approval process. Benefit of laboratory spectrophotometer is to assist on correcting the formula i.e. to minimize the colour difference versus standard. Some customers have their own requirements for ΔE-value.

Different lightings are a challenge for tinting. Colour can vary in different lighting conditions. This is often the case, for example, with yellow colours. Most colour recipes are accepted in daylight. If wished, the colour can be made for other light conditions. Film thickness and surface or primer colour affect to the final appearance of the shade. All of these items need to be considered when making a new colour recipe.

The new colour formula can only be approved after completely dried – a wet sample does not illustrate the colour completely. To be safe, room temperature drying is the best choice. Drying in elevated temperature tends to change the shade, in particular, in epoxies. Water-borne coatings require also special attention. The evaporation of water needs to be taken into account, as water-borne coatings typically become considerably darker as they dry.

Tinting coordinator Kristiina Parkkila

In addition to the colour recipes made for our existing portfolio, Nor-Maali’s tinting department is closely involved in our R&D. Tinting coordinator Kristiina Parkkila explains how to start working with the colours of the new product. When the new product is still in the product development / testing phase, tinting phase is also started.

The first step is to ensure the compatibility of the coating and the tinting pastes. This is the most vital step, because, in the worst case, technical performance is negatively affected. As part of the tinting, stability is measured and adjusted.

The opacity of the coating and number of bases are already considered and decided during the initial product development phase. In addition to different degrees of whiteness i.e. bases, coloured base coatings are a great way to improve the opacity. For example, the yellow shades have better opacity when tinted to yellow base.

When the base colours are ready, Parkkila characterizes them. In this procedure, the spectrophotometer measures the whiteness of the base colour and calculates the colour formulas. We always do first RAL and NCS S colours and then other colours on demand. The tinting software provides for Parkkila the starting formula – she checks visually and corrects the formula. The colour is tinted into the coating, the coating is dried and the colour is compared to the colour standard. The accuracy of the quick formulas depends on e.g. product, tinting rules, opacity, colour chart, and colour range.

Parkkila tells about her work: “In addition to new products, my daily work is mainly to create colours for existing coatings. The colours include both standard colours and customer-specific colours from shade models received from customers.” She also maintains tinting software (customer updates), provides shade pricing information for the sales, and advises dealers on tinting related questions.

Parkkila likes her work because of its versatility – “being able to match unique colour is rewarding”. Parkkila has 20 years of experience in tinting: “Every day with tinting is different, a lot of learning by doing and experimenting”.

If you have any questions regarding tinting, please contact the Nor-Maali Tinting Department.

Kristiina Parkkila Jere Juntunen

Tinting coordinator Tinting

mob. 040 773 6440 mob. 044 370 0539